nanojet

"the fascination of flight can't be expressed with words. But it really lies beyond the capabilities of human endeavor - Sir Richard Branson

about nanojet

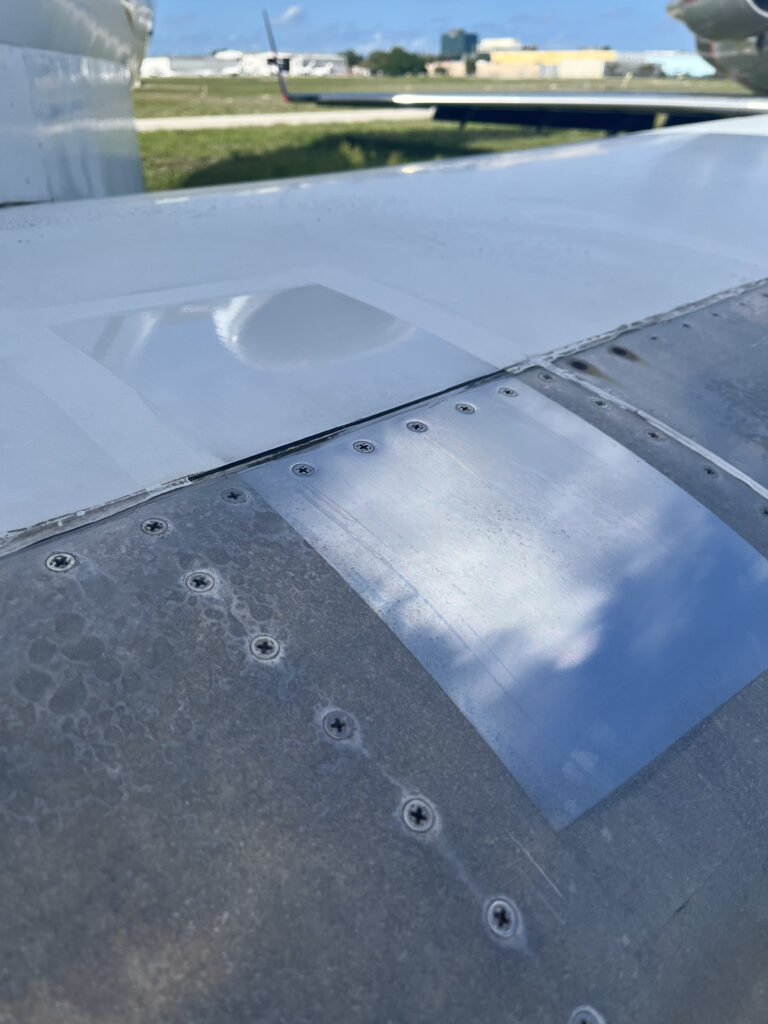

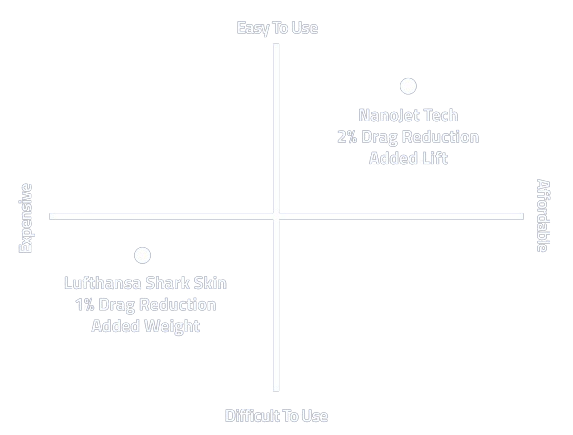

NanoJet Tech is a unique clear Ceramic Coating that produces a significant decrease in the collective surface drag coefficient on the aircraft exterior resulting in tremendous fuel savings.

2% DRAG REDUCTION AND 15% MORE LIFT!

- Bonding on contact to become an invisible shield.

- Applied directly over existing paint, it protects against abrasion, corrosion, oxidization, fire, and UV degradation.

- Ice formation retardant / Hydrophobic.

- Green, renewable, non-toxic, VOC exempt, NSF-51 certified.

- FDA Food Grade compliant and GRAS certified.

- Weight – less than 20 lbs (dry) or can be used as a paint replacement saving 600 lbs – 1,200 lbs per aircraft.

- USA designed and manufactured,

- Hydrophobic

- More Lift – Less Drag

- Self-cleaning – Anti-icing

- Reduced Carbon Footprint

- Military-Grade Technology – Made in USA

- Long-Lasting – Anti-Corrosion & Oxidation

- UV Blocking Extends Paint Life – Aesthetic Enhancing

- Cost Reduction Through Fuel And Maintenance Savings

MEETING CO2 EMISSION STANDARDS EFFECTIVELY, TIMELY, AND AFFORDABLY

NanoJet Technology has been military tested, NASA inspired, and perfected to produce proven results.

Easily applied by Electrostatic Sprayer creates a new ultra-smooth surface with no voids, holes, or irregularities, resulting in significantly more fuel-efficient flying.

EXAMPLE SAVINGS

1x (smaller) Aircraft … Fuel per Annum @ $5,500,000

2% Drag reduction = $110,000 x 100 planes = $11,000,000

1x (Larger) Aircraft … Fuel per annum @ $22,000,000

2% Drag Reduction = $440,000 x 100 planes = $44,000,000

(based on $2.50 per gallon)

Providing affordable coating applications for aviation to meet FAA and governmental CO2 emission standards.

The quantifiable VALUE of NanoJet Tech coating will save $ billions in annual fuel costs and maintenance globally

MORE LIFT LESS DRAG

- 2% Drag Reduction.

15% Lift Increase. - No Added Weight – Less 20 lbs.

- Ice Formation Retardant.

- Anti Corrosion.

Designed specifically for Aviation.

Highest percentage of pure Nanoceramic ingredients (32%) for definitive performance.

Ease of application and maintenance.

NANOJET TECH

Available now (first time) for commercial application.

Manufacturing unique chemistry solutions for over 30 years.

OTHER PRODUCTS AVAILABLE!

Our current clients include the USA military (Army, Airforce, Navy), Aerospace (Space X, Blue Origin), and Marine and commercial sectors.

NJT210 NANOJETTECH CFR1

Our exclusive NanoCeramic/graphene coating that has a Coefficient of Friction (CoF) of 0.034µ. Wind tunnel test verify that (CoF) 0.034µ produces and qualitatively equals 1% reduction in surface drag and a 30% increase in lift on airfoil wing shape. This 1% reduction of surface drag on aircraft test wing is uniquely also creating 30% increase in lift which has never been seen before on any wind tunnel test. This defies Bernoulli’s Principle which is the scientific basis for the parameters that define the laws of flight recognized by NASA and all aerospace engineering. The real world mathematic results is millions of gallons of fuel saved annually from more efficient and faster aircraft. This coating also show positive results in permanent de-icing capabilities. Coating effectiveness on real airplanes with normal flight hours is still performing at five years and should last 8-10 years from one application.

NJT212 NANOJETTECH CFR2

Our exclusive Nanoceramic/graphene coating that has a Coefficient of Friction (CoF) of 0.023µ. This 0.023µ (CoF) mathematically should equal a 2% reduction in surface drag and theoretically create more than 30% increase in lift also possibly doubling fuel savings of the previous NANOJETTECH CFR1.

NJT205 NANOJETTECH CFR3

Our exclusive Nanoceramic/graphene coating has an amazing Coefficient of Friction (CoF) of 0.015µ. This formulation should mathematically produce three times the surface drag reduction as well as much more than 30% lift based on initial wind tunnel testing. This could result in three times the fuel savings and de-icing potential as well for all aircraft types.